Environmentally-conscious manufacturing at Sony

Better products for both customers and the environment

At Sony, we aim to create better products for both our customers and the environment. Our environmental plan “Road to Zero”1 means understanding product impact over the whole life cycle including resource procurement, manufacturing, logistics, use by customers, recycling, and disposal, and pursuing environmental initiatives at manufacturing sites.

![Diagram showing life cycle of a product from manufacturing to recycling material, with labels: [1] Manufacturing of products at factory sites [2] Logistics [3] Use of products by customers [4] Resource extraction and disposal [5] Recycling sites [6] Manufacturing of parts by suppliers [7] Resource extraction](https://cdn.statically.io/img/d1ncau8tqf99kp.cloudfront.net/OOFM/images/eco-plant-environment/desktop/2-d.jpg)

[1] Manufacturing of products at factory sites [2] Logistics [3] Use of products by customers [4] Resource extraction and disposal [5] Recycling sites [6] Manufacturing of parts by suppliers [7] Resource extraction

Energy

While electricity is essential for manufacturing, we strive to reduce energy consumption and the environmental impact of the products we deliver, including the associated greenhouse gas emissions.

More energy-efficient machinery

We are contributing to energy conservation by introducing high-efficiency chiller, air conditioning, and inverter-based equipment at manufacturing sites. For example, Sony EMCS (Malaysia) Sdn. Bhd (SOEM) have introduced high-efficiency chiller equipment specifically to save energy. Normally, large amounts of cold water are required to air-condition production areas, using large pumps. By using compact individual pumps for each air conditioner and a management system that operates them only as necessary, the power consumption has been reduced by about 40%2.

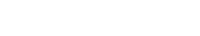

Difference between a general air conditioning system (left) and the system introduced at SOEM (right) [1] Large pumps in constant operation [2] Chiller equipment [3] Small pumps operating only as required [4] High-efficiency chiller equipment

High-efficiency chiller

Compact pumps

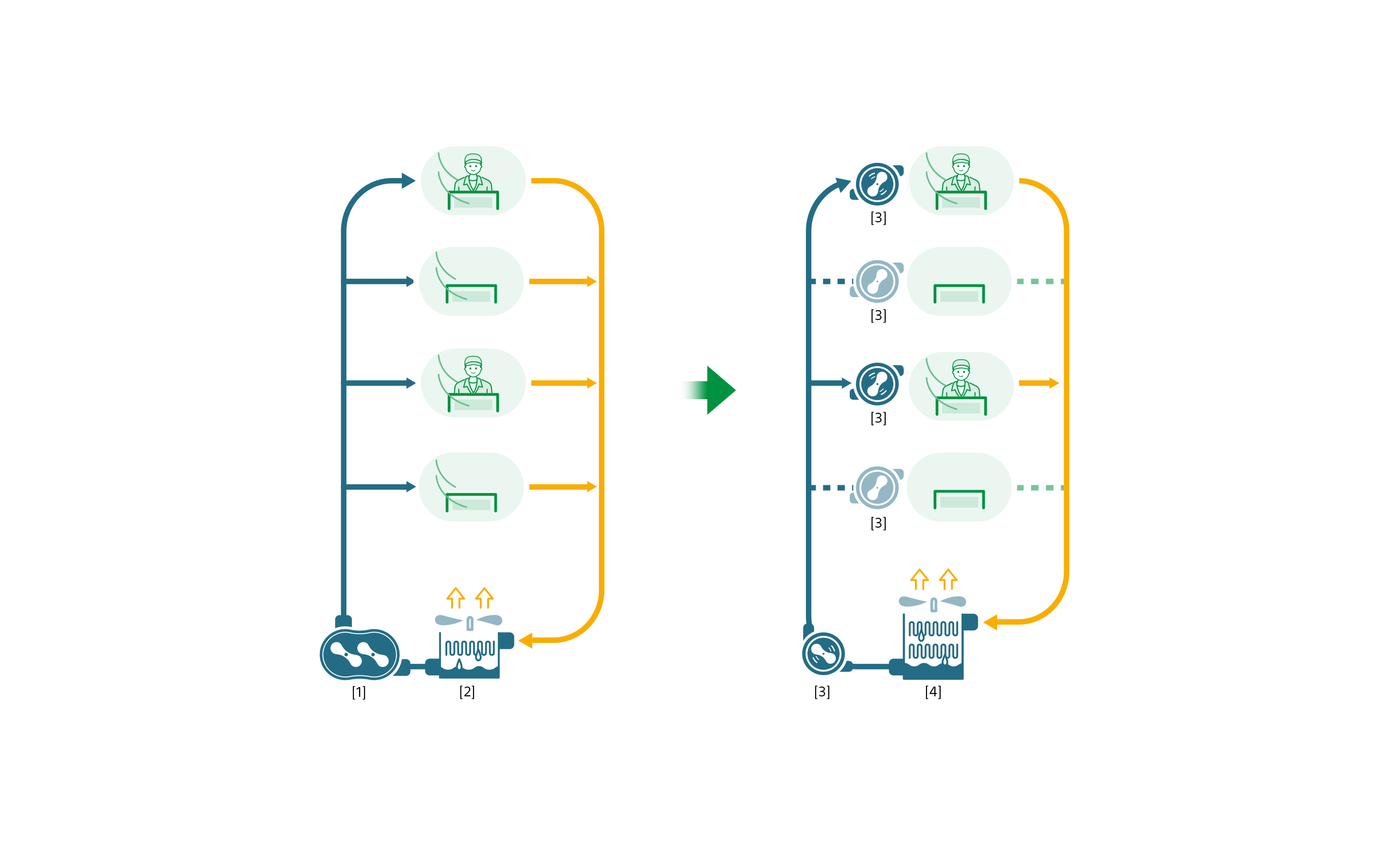

Visualising electricity consumption

We also pursue a series of small-scale eco-activities such as turning off power on holidays, using LED lighting, and managing air conditioning, which combined can contribute to factory energy savings. At the Kohda site in Japan, electricity consumption is visualised to raise environmental awareness. We aim to combine our strengths in sensing and measurement to establish new environmental technologies such as IoT-based environmental monitoring.

Panel at Sony Global Manufacturing & Operations Corporation,

Kohda manufacturing site for visualisation of electricity consumption

Building to 100% renewable electricity use

Sony Group aims to achieve 100% renewable electricity use by 2030, through combination of measures including the introduction of solar panels and the purchase of renewable electricity certificates. In Sony's Entertainment, Technology & Service business group (ET&S), we are close to achieving 100% renewable electricity with just Japan/East Asia region and Pan Asia region remaining to complete the transition in the 2023 fiscal year.

Roof of Sony Technology (Thailand) Co., Ltd. with solar panels, a renewable electricity source that does not emit greenhouse gases.

Resources and water

To reduce our environmental impact, we are reviewing the resources and water used in manufacturing, and aiming to minimise waste produced by our facilities.

Reusing and recycling of secondary materials

Waste is being reduced by reusing and recycling secondary materials such as the packaging used for transporting parts. In 2021, Shanghai Suoguang Visual Products Co., Ltd.3 recycled and reused a total of 1.9 million cushioning airbags, 3,000 cartons to transport TV panels, and 15,000 cartons to protect parts transported by air cargo.

Reused cushioning materials (left) and cartons for transporting TV panels (right)

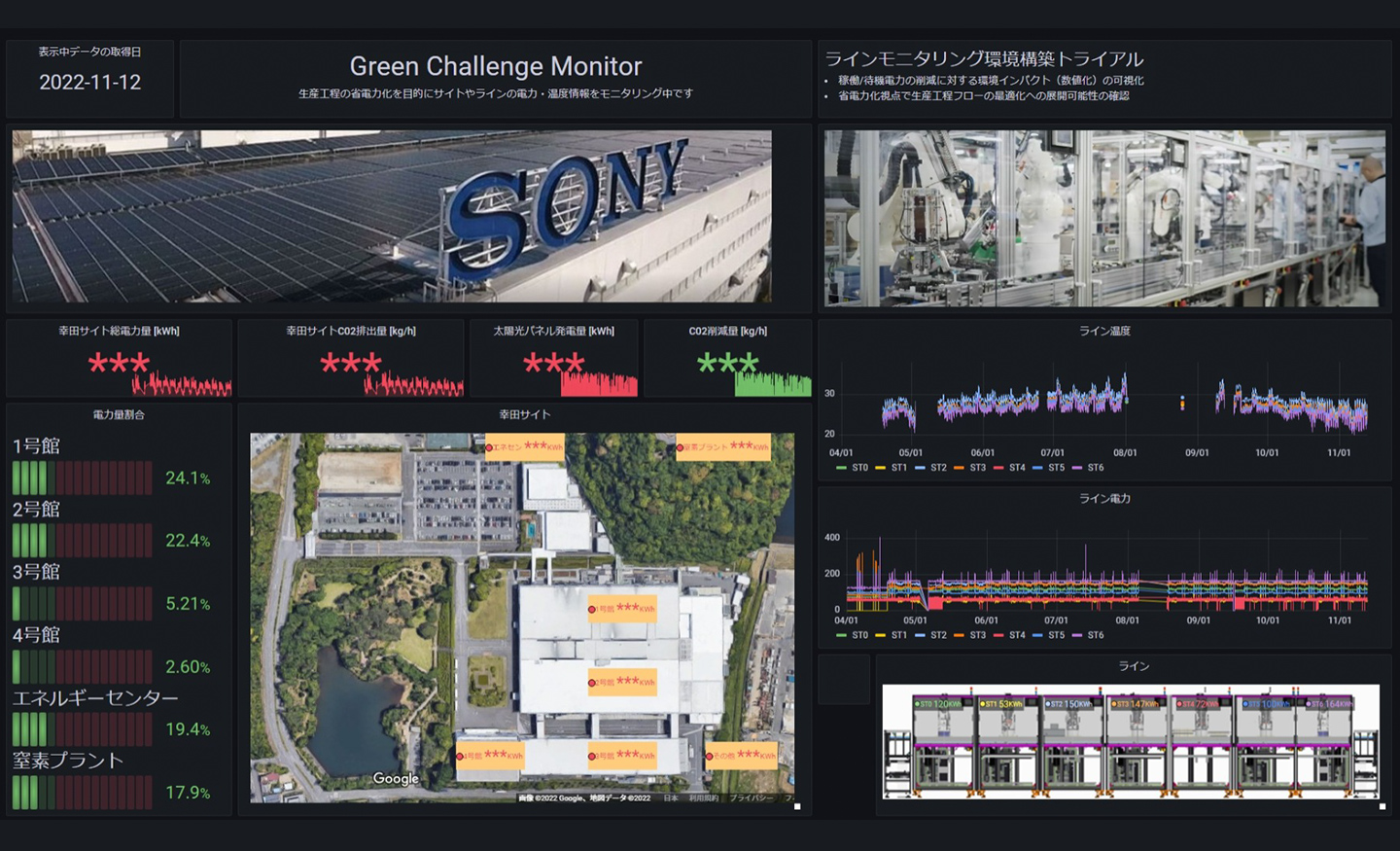

Aiming for zero landfill contribution

We target a landfill use rate of 1% or less. Through its waste reduction efforts, Sony Technology (Thailand) Co., Ltd. has achieved a sustained landfill rate under 0.1% since 2020, and will aim to maintain this value going forward.

[1] Landfill waste ratio of Sony Technology (Thailand) Co., Ltd.

[2] Landfill waste by percentage [3] Landfill waste target

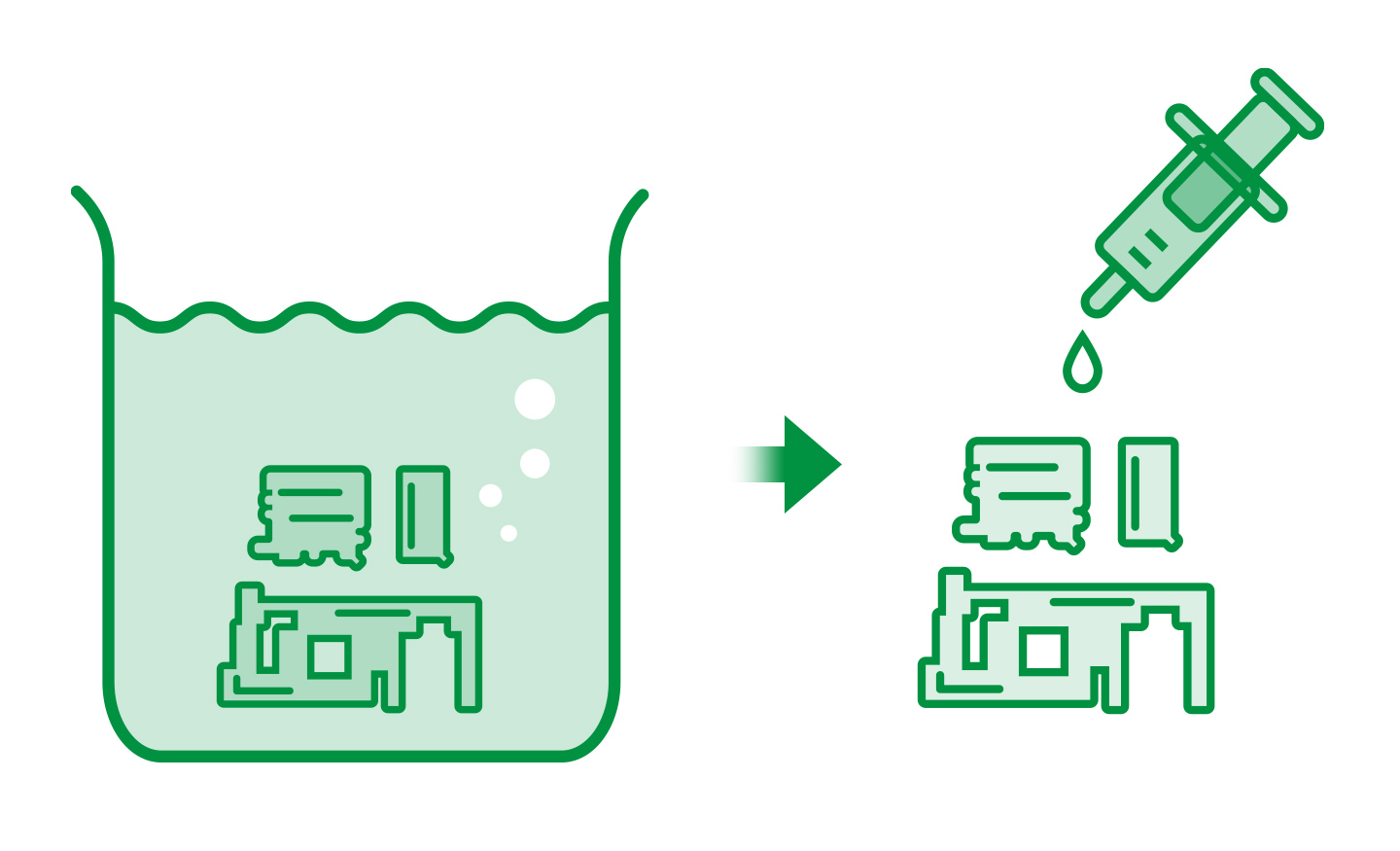

Water recycling

In ET&S, we are working to reuse water used for cleaning parts, air conditioning condensate, rain and well water. Sony Digital Products (Wuxi) Co., Ltd. (SDPW) (China) has relocated pipes to the roof for easier leak detection and repair.

Reducing Chemical Usage

Chemicals and solvents are being used more efficiently, taking disposal into account, while maintaining manufacturing and product quality. For example, SDPW were able to reduce the quantity of alcohol cleaning solution used by 84 kg from the previous year.

Manufacturing and biodiversity

It is essential that manufacturing sites coexist in harmony with the communities of which they are a part. Sony employees in various countries and regions are encouraged to work with their local communities to maintain parks and forests, and participate in biodiversity conservation and cleanups.

Sony Global Manufacturing & Operations

Various events are held at Sony Forest, on the Kohda site in Japan for employees and their families. They help to deepen awareness of the environment and health and to promote voluntary efforts. Events include nature walks through the Sony Forest and a variety of activities for children, such as woodworking and crafts.

Sony Technology (Thailand) Co., Ltd.

Sony Technology (Thailand) Co., Ltd. has held environmental activities at Khlong Tamru Environmental Education Center in Chonburi. Volunteer employees from both Chomburi and Bangkadi manufacturing sites participated in local mangrove tree-planting activities.

Sony Digital Products (Wuxi) Co., Ltd. (SDPW)

Since 2018, SDPW, in cooperation with the Wuxi New District Civic Office and the Ministry of Ecology and Environment, has established 16 volunteer groups within the city to carry out community cleanup activities. As of October 2022, roughly 700 volunteers have participated in 177 cleanups, collecting around 5 tons of trash.

Sony EMCS (Malaysia) Sdn. Bhd.

In addition to planning beach cleanup activities as part of Sony's One Blue Ocean activities and participating in community cleanup activities, Sony EMCS (Malaysia) Sdn. Bhd. set up an event booth with its cooperating partners to educate the public on how to properly dispose of household electronic waste, and also offered a collection service for such waste at the booth.

Shanghai Suoguang Visual Products Co., Ltd.

Shanghai Suoguang Visual Products Co., Ltd. has been developing cooperative farming4 activities both internally and externally since 2021. Outside the company, it has been practicing cooperative farming and conducting educational activities with the Shanghai Pudong New Area Tangzhen Association for the Disabled and the Tangzhen Children's Service Center to help promote understanding of the symbiosis between people and nature.